Wagner magnets

Technology that attracts

Concentrated expertise from more than 85 years of experience coupled with a spirit of innovation and the courage to face any challenge - that is what characterises WAGNER MAGNETE. Together with our customers, we provide standard and customised solutions worldwide for every situation involving industrial magnets. Specialising in clamping and holding magnets as well as magnetic separators, we guarantee the quality and durability of our products.

We are constantly developing, testing and optimising our products and your individual solutions in our own technical centre in order to be able to offer you perfect quality and the best support. This allows us to expand our technical expertise with every new project.

We provide you with detailed and honest advice on the feasibility of your requirements and look forward to a close and productive working relationship. Whether reliable standard or customised, we turn your wishes into reality.

The right magnet

For your area of application

For your area of application

What do you want to lift, repel, sort, search for or demagnetise? Whatever task you are facing, we will make your challenge ours.

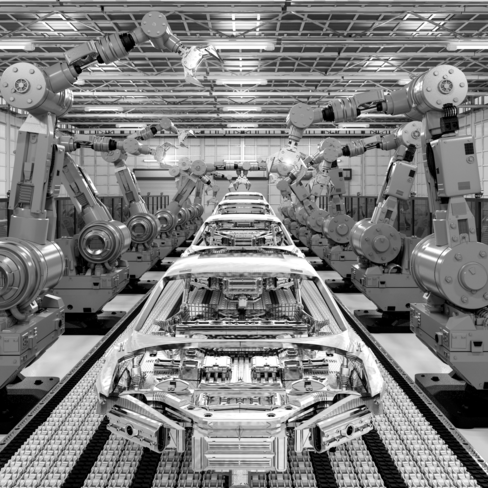

We offer magnets and magnet solutions for various industrial applications, such as mechanical engineering, the automotive industry, medical technology, the aerospace industry and renewable energies.

Thanks to our long-standing partnerships with our customers, we know exactly what is important in your industry and can offer you both standard products and customised solutions. In any case, we supply you with magnets that are precisely tailored to your requirements - in certified Wagner quality.

Magnet technology at the Wagner Technical Centre

Your way to customised magnet technology

Practical tests, customised solutions and in-depth expertise

Discover and test the limitless possibilities of magnetic technology in our state-of-the-art test facility . We accompany you on your journey to find customised solutions for your individual requirements and together we create the perfect symbiosis of technology and efficiency. Your vision is what drives us.

Ready to see the power of magnetic technology in action? Visit our technical centre and discover how our technology can drive your business forward. Let's shape your success together.

Career opportunities at Wagner Magnete

Your path to success starts here

Development opportunities, training and further education and personal growth - shape your career in an innovative and future-orientated industry.

Shape your professional future at WAGNER MAGNETE. We are proud to offer our employees a wealth of opportunities for personal and professional development . With positions in a wide range of areas and opportunities for internal promotion, we see ourselves not just as a place to work, but as a place where careers grow and develop. Whether you are at the beginning of your career and looking for an apprenticeship or internship, or you already have experience and are looking for new challenges , WAGNER MAGNETE is the right place for you. Discover the opportunities.